Number of Bars

Series No:

Weight:(g/pcs)

Dimension:(mm)

Specification:

Inquiry

Description:

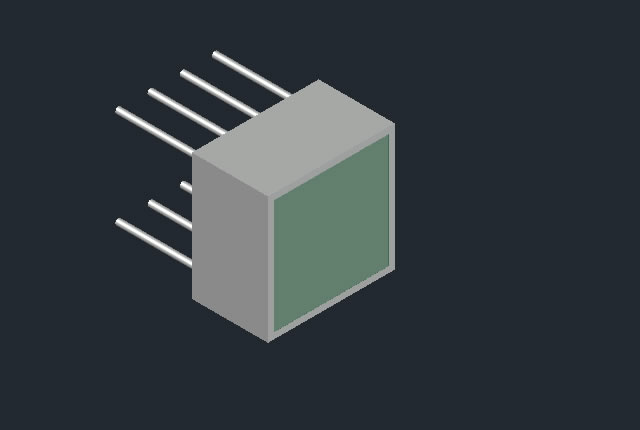

“Precision Illumination: Exploring the 10×10mm LED Light Bar for Modern Displays”

Introduction

In the fast-evolving world of electronic displays, visual clarity, uniform brightness, and compact design are crucial. The LED light bar—specifically the square, 1-bar model measuring 10.00 × 10.00 mm—is a versatile solution designed for engineers seeking reliability and consistent illumination in compact form factors. As part of the modern LED bar graph family, it delivers crisp light output and precise visual indication in measurement systems, dashboards, and signal equipment.

The LED light bar provides a clean, high-intensity output ideal for industrial panels, audio level meters, and control systems. Its unique design supports stable, even lighting with minimal power consumption. This component bridges aesthetic appeal and functional excellence, offering engineers and designers a dependable, energy-efficient LED bar display that enhances the user interface in both industrial and consumer applications.

Features of the 10×10mm LED Light Bar

The 10.00 × 10.00 mm LED light bar represents a perfect balance between compact size and strong luminous performance. Built using advanced surface-mount and encapsulation technology, it ensures long-term durability and high optical stability.

Key Features Include:

-

Compact Square Design (10.00 × 10.00 mm):

Its uniform size and square shape enable easy integration into multi-bar modules, ideal for sleek layouts or Bar Graph Arrays. -

High Brightness and Clarity:

Produces vivid, uniform illumination suitable for both single and multi-indicator applications. -

Low Power Consumption:

Engineered for energy efficiency, ensuring longer life and reduced operational costs. -

Wide Viewing Angle:

Offers consistent brightness across broad angles—essential for panel-mounted or horizontal indicators. -

Long Operational Lifespan:

The diode construction guarantees over 50,000 hours of continuous performance with minimal degradation. -

Excellent Color Consistency:

Available in various colors (red, green, yellow, blue), maintaining stable output across temperature variations. -

Surface-Mount Compatibility:

Easy installation in automated PCB processes, improving assembly precision and reducing production time. -

Thermal Stability:

Efficient heat dissipation ensures reliability even under continuous operation in demanding environments.

Applications of the LED Light Bar

The LED light bar is more than a simple indicator—it’s a versatile illumination tool used across diverse industries. From instrumentation to audio equipment, its design makes it a favorite among engineers and manufacturers worldwide.

1. Industrial Control Panels

Used to indicate system status, power levels, or fault warnings. The LED bar graph configuration helps operators visualize data intuitively.

2. Audio Equipment

Acts as a level meter for visualizing sound intensity or volume peaks, delivering fast response and eye-catching illumination.

3. Measurement and Test Instruments

The LED bar display provides an accurate visual readout of analog or digital signals, often replacing mechanical gauges.

4. Medical Devices

Used in diagnostic and monitoring equipment where precise, low-glare illumination is essential for user clarity.

5. Automotive Displays

Serves as a visual cue for battery levels, temperature, and other dashboard indicators.

6. Smart Appliances

Enhances the user interface with modern, backlit design indicators that add both functionality and visual appeal.

7. Consumer Electronics

Perfect for equipment like power amplifiers, routers, or data displays, providing bright, clear signal representation.

Benefits of the 10×10mm LED Light Bar

The LED light bar offers a series of advantages that make it a go-to choice for engineers and designers aiming for quality and dependability.

-

Precision Illumination:

Its optical clarity ensures brightness without glare, making it ideal for displays requiring exact light control. -

Design Flexibility:

Multiple bars can be arranged to form Bar Graph Arrays, enabling creative and data-rich visualization in compact spaces. -

Energy Efficiency:

Consumes significantly less power than traditional incandescent indicators while offering greater brightness. -

Reliability:

Solid-state construction means no filaments or mechanical wear, allowing it to withstand vibrations and temperature variations. -

Longevity:

Built for extended operation, maintaining brightness consistency across thousands of hours of use. -

Cost-Effective Integration:

Simplifies PCB layout and reduces component count compared to traditional multi-indicator systems. -

Customization Options:

The LED bar display can be configured in multiple color variations or brightness levels based on specific project needs.

Case Studies

Case Study 1 – Industrial Process Indicators (Germany):

A major manufacturing company integrated the 10×10mm LED light bar into their process control panels. The result was improved operator visibility, reduced maintenance downtime, and 30% energy savings compared to older display modules.

Case Study 2 – Audio Level Displays (USA):

An audio equipment manufacturer used LED bar graphs as visual equalizer displays. The high refresh rate and color uniformity of the led 1806-based technology enhanced user experience and product aesthetics.

Case Study 3 – Medical Diagnostics (Japan):

In compact medical analyzers, the LED light bar provided color-coded operation indicators with minimal heat emission, improving both safety and functionality.

User Testimonials

John M., Senior Electronics Engineer (UK):

“We chose the 10×10mm LED light bar for our control panels. Its brightness and precision helped improve real-time visibility under any lighting condition.”

Elena R., Product Developer (Spain):

“The square LED bar module provided a sleek design and consistent light output, which made our devices look more professional and modern.”

David C., Automation Specialist (Canada):

“These LED bar displays are robust and energy-efficient—ideal for 24/7 industrial systems. We haven’t had a single failure in over two years.”

Integration and Design Considerations

For best results, integrating the LED light bar into a diode-based circuit requires proper current regulation and layout planning.

Key Tips:

-

Use Constant-Current Drivers:

Maintain consistent brightness and protect LEDs from current fluctuations. -

Thermal Management:

Include heat sinks or thermal vias on PCBs for continuous operation in confined environments. -

Uniform Layout:

Align multiple LED bar graph units evenly to ensure consistent brightness in linear or square configurations. -

Protective Components:

Use resistors and diodes to prevent voltage spikes during system start-up or switching.

Following these practices ensures optimal performance, stability, and long life of the Bar Graph Arrays.

Conclusion

The 10×10mm LED light bar stands out as a compact, durable, and efficient solution for modern electronic displays. Whether implemented as a LED bar graph for audio visualization or as a LED bar display in industrial control panels, it offers unmatched clarity, stability, and performance.

Its small footprint, high brightness, and flexibility make it an essential component in today’s advanced designs. For engineers and system integrators seeking reliable, energy-efficient illumination, the LED light bar remains the ideal choice—capable of transforming simple visual indicators into professional, high-impact displays.

Features

- Display Area Shape: Square, providing a distinct and clear illumination area.

- Display Area Number: Features one display area.

- Reflector Dimensions: Both the length and width are 10.00mm, making it compact and easy to integrate.

- Uniform Light Emitting Area: Ensures consistent and even lighting across the entire display.

- Low Current Operation: Energy-efficient, reducing electrical power consumption.

- Wide Viewing Angle: Allows the display to be easily visible from various viewing angles.

- Easily Mounted on P.C. Boards: Designed for straightforward integration into electronic systems.

- Flush Mountable: Can be installed to align seamlessly with the mounting surface, providing a neat appearance.

- Excellent On/Off Contrast: Offers clear visibility, enhancing the distinction between the illuminated and non-illuminated states.

- Can be Used with Panels and Legend Mounts: Versatile in terms of installation, suitable for various panel types.

- Categorized for Luminous Intensity: Ensures uniform brightness across different units.

- Different Colors in One Unit Available: Provides options for various color displays, enhancing customization.

- Standard: Black Face, White Segment: Offers a classic and easily readable appearance.

- RoHS Compliance: Manufactured in accordance with environmental and health safety standards.

Applications

- Indicator Lights: Ideal for use in compact spaces requiring clear indicator lights, such as in electronics or machinery.

- Control Panels: Suitable for small control panels in vehicles, industrial machinery, or consumer appliances.

- Compact Signal Lights: Applicable in settings where space-saving signal lights are needed.

- Instrumentation Displays: Useful for small-scale instrumentation where clear display is necessary.

- Consumer Electronics: Can be integrated into various consumer electronic devices for display or indication purposes.

- Safety and Emergency Equipment: Appropriate for compact safety devices requiring clear indicator lights.

- Information Displays: Effective in small-scale information displays in public areas or systems.

Electrical-optical characteristics:

Package configuration & Internal circuit diagram

Obtain 3D specification files

To examine all 3D specifications, save the files to your local drive and open them with your 3D application.

Lens colors in 3D files are solely for visual representation; consult the Datasheet for accurate lens type and color information.

In the event of a mismatch, the dimensions in the datasheet take precedence over the 3D specifications.

All dimensions are in millimeters(inches)

Tolerance is +-0.25(0.01″) unless otherwise note

Specifications are subject to change without notice.

Partno description:

Related Information

Applied for:

1. Application

The Seven Segment LED is widely applied for ordinary electronic equipment (such as office equipment,

communication equipment and household applications). Checking with BETLUX’s Sales in

advance for information on applications in which exceptional reliability is required, particularly

when the failure or malfunction of the LEDs may directly jeopardize life or health (such as in

aviation, transportation, traffic control equipment, medical and life support systems and safety

devices).

2. Storage

The storage ambient for the Seven Segment LED should not exceed 30℃ temperature or 70% relative humidity.

For extended storage out of their original packaging, it is recommended that the Seven Segment LEDs be stored

in a sealed container with appropriate desiccant, or in a desiccator with nitrogen ambient.

3. Cleaning

Avoid using any unspecified chemical solvent to clean LED . For example, Trichloroethylene, Chlorosen, Acetone, and Diflon S3MC.

Any cleaning method can only be taken under normal temperature in one minute or less if it is required.

Use water to clean the Seven Segment LED if necessary under room temperature

dry it immediately after that.

4.Forming

Any unsuitable stress applied to the epoxy may break bonding wires in LED

Any forming on lead pin must be done before soldering, not during or after soldering.

Avoid applying any stress to resin in order to prevent the epoxy fracture and break on bonding wire.

While forming, please use a tie bar cut or equivalent to hold or bend the pin.

2mm from the base of resin is the minimum distance for the place bending the lead pin.

Avoid bending the lead pin at the same point twice or more.

Soldering

When soldering, leave a minimum of 2mm clearance from the base of the base of the lens to the soldering point. Dipping the lens into the solder must be avoided.

Do not apply any external stress to the lead frame during soldering while the LED is at high temperature.

Recommended soldering conditions:

| IR Reflow Soldering (for SMD display) | Wave Soldering | Soldering Iron | |||

| Pre-Heat | 150-180°C | Pre-Heat | 100°C Max. | Temperature | 300°C Max. |

| Pre-Heat Time | 120sec Max. | Pre-Heat Time | 60sec Max. | ||

| Peak Temperature | 260°C Max. | SolderWave | 260°C Max. | Soldering Time | 3sec Max.(one time only) |

| Soldering Time | 10 sec Max. | Soldering Time | 5sec Max. | ||

Note: Excessive soldering temperature and/or time might result in deformation of the LED lens or failure of the LED

ESD(Electrostatic Discharge)

Static Electricity or power surge will damage the LED.

Suggestions to prevent ESD (Electrostatic Discharge):

n Use a conductive wrist band or anti-electrostatic glove when handling these LEDs

n All devices, equipment, and machinery must be properly grounded

n Work tables, storage racks, etc. should be properly grounded

n Use ion blower to neutralize the static charge which might have built up on surface of the LED’s

plastic lens as a result of friction between LEDs during storage and handling

ESD-damaged LEDs will exhibit abnormal characteristics such as high reverse leakage current,

low forward voltage, or “no light on” at low currents. To verify for ESD damage, check for “light on”

and Vf of the suspect LEDs at low currents.

The Vf of “good” LEDs should be>2.0V@0.1mA for InGaN product and >1.4V@0.1mA for AlInGaP

product.

LED dirve IC by Maxim Integrated

MAX6959 4½-Digit LED Display Driver

MAX6958 4½-Digit LED Display Driver

MAX6955 7-, 14-, 16-Segment LED Display Driver

MAX6956 LED Static Display Driver and I/O Port

MAX6954 7-, 14-, 16-Segment LED Display Driver

MAX6952 5 x 7 Matrix LED Display Driver

MAX6957 LED Static Display Driver and I/O Port

MAX6950 5-Digit LED Display Driver

MAX6951 8-Digit LED Display Driver

ICM7212 4-Digit LED Driver

ICM7212A 4-Digit LED Driver

ICM7212AM 4-Digit LED Driver

ICM7212M 4-Digit LED Driver

ICM7218A 8-Digit LED Driver

ICM7218B 8-Digit LED Driver

ICM7218C 8-Digit LED Driver

ICM7218D 8-Digit LED Driver

MAX7221 8-Digit LED Display Driver

MAX7219 8-Digit LED Display Driver

When selecting power for LED systems, it’s essential to understand several key parameters to ensure safe operation, longevity, and optimal performance. Here are some steps and considerations for LED power selection:

- Determine the Forward Voltage (Vf) of the LED(s):

Each LED has a forward voltage, which is the voltage at which the LED operates when the current is flowing through it. This value can typically be found in the LED’s datasheet.

- Determine the Forward Current (If) of the LED(s):

The forward current is the current at which the LED is designed to operate. Running an LED at higher than its rated current can reduce its lifespan and increase the heat it produces.

- Decide on the Configuration:

Series Configuration: When LEDs are connected in series, the forward voltages add up, but the current remains the same.

Parallel Configuration: When LEDs are connected in parallel, the forward voltage remains the same, but the currents add up. This configuration can be risky because if one LED fails or has a slightly lower forward voltage, it can cause the other LEDs to draw more current.

Calculate Total Power Requirements:

Power (W) = Total Forward Voltage (V) x Total Forward Current (A)

For example, if you have three LEDs connected in series, each with a forward voltage of 3V and a forward current of 20mA, the total power requirement would be:

Power = (3V + 3V + 3V) x 20mA = 9V x 0.02A = 0.18W

- Select an Appropriate Power Supply:

- Voltage Rating: The power supply voltage should match or slightly exceed the total forward voltage of your LED configuration.

- Current Rating: The power supply’s current rating should meet or exceed the total forward current of your LED configuration.

- Safety Margin: It’s a good practice to select a power supply that can provide at least 20% more power than your calculated requirement. This ensures the power supply isn’t operating at its maximum capacity, which can extend its life and ensure safer operation.

- Consider Additional Features:

- Dimming Capability: If you want to control the brightness of your LEDs, choose a power supply with dimming capabilities.

- Overcurrent and Overvoltage Protection: To protect your LEDs, select a power supply with built-in protection mechanisms.

- Thermal Management: Ensure that the power supply has adequate cooling, especially if it will be enclosed or in a location with limited airflow.

- Regulation and Efficiency:A power supply with good regulation will maintain a consistent voltage output despite variations in the load. High efficiency ensures minimal power is wasted as heat.

- Physical Size and Form Factor:Depending on where you plan to place the power supply, its size and shape may be critical factors.

In summary, when selecting power for LED systems, understanding your LED’s requirements and the configuration you plan to use is essential. Then, pick a power supply that meets those needs with some added safety margin, keeping in mind any additional features or constraints relevant to your project.

Here are some well-regarded brands in the industry:

- Mean Well: One of the most recognized brands in the LED power supply industry, Mean Well offers a wide range of products suitable for both indoor and outdoor applications. Their units often come with features like overcurrent protection, dimming capabilities, and high efficiency.

- Tridonic: A global leader in lighting technology, Tridonic offers LED drivers and power supplies that cater to various lighting solutions, from simple setups to advanced smart lighting systems.

- Philips Advance Xitanium: Philips is a well-known brand in the lighting industry, and their Xitanium series of LED drivers are known for reliability and performance. They cater to both indoor and outdoor LED applications.

- Osram: Another giant in the lighting industry, Osram offers a range of LED drivers and power supplies suitable for various applications, including architectural and street lighting.

- LIFUD: Specializing in LED drivers, LIFUD is known for its high-quality products that cater to both commercial and residential LED lighting solutions.

- MOSO: This brand offers a variety of LED drivers, especially for outdoor and industrial applications. Their products are known for durability and performance.

- TDK-Lambda: With a history in power electronics, TDK-Lambda offers a range of power supplies and LED drivers suitable for various applications, emphasizing reliability and advanced features.