3mm Quad-Level Circuit Board Indicator

Article No:

Color:

Weight:(g/pcs)

Dimension:(mm)

Inquiry

Product Series information

Product Series |

|---|

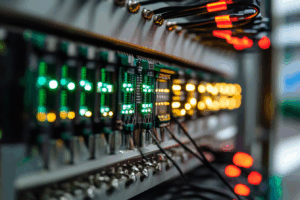

Series No:bl-la4d3-a2004 Dimension 7.9 × 9.15 × 11 mm Description: ___________________________________________________________________________________________________________________________________________________ 3mm Quad-Level LED CBI – Multi-Color Circuit Board Indicator (10×4×20mm)The 3mm Quad-Level LED CBI (Circuit Board Indicator) is engineered for applications that demand high-density visual signaling within a compact panel or PCB footprint. With a vertical quad-level configuration, this indicator features four precisely aligned LED positions, making it ideal for multi-status displays, step indicators, and stacked signal interfaces. Measuring 10×4×20mm, this module delivers efficient illumination, excellent contrast, and long-term reliability across industrial, commercial, and consumer applications. Available in single-color, bi-color, tri-color, and four-color combinations, the quad-level CBI offers unmatched flexibility for system designers needing multiple states or status signals in one compact, unified assembly. Key Features✔ Quad-Level Vertical LED ArrangementThe four stacked LED positions allow designers to represent multi-step status levels, progress indicators, signal hierarchies, or operational sequences without increasing horizontal board space. This is especially beneficial for compact devices, dense PCBs, and front-panel arrangements. ✔ 3mm LED Package for Universal CompatibilityThe standard 3mm round LED format ensures compatibility with existing footprints, fixtures, and light guide systems. This size provides a balance of brightness, durability, and lens options to suit a wide range of interface designs. ✔ Pre-Formed Leads for Precision AlignmentEach LED level includes pre-formed, consistent lead spacing to guarantee perfect alignment when mounted on the PCB. This eliminates manual lead bending, reduces assembly errors, and ensures highly uniform installation during mass production. ✔ High-Contrast Black HousingThe PA66 black housing reduces stray reflection and enhances LED contrast, providing superior readability across ambient lighting conditions—ideal for industrial control rooms and device dashboards. ✔ Long-Life LED Chip TechnologyBuilt with high-efficiency LED chips, each indicator offers:

This ensures consistent system performance and reduces maintenance requirements. ✔ Industrial-Grade Materials & Compliance

✔ Multi-Color OptionsAvailable configurations include:

These variants allow designers to create layered visual signals without requiring multiple indicator modules.  ApplicationsThe 3mm Quad-Level LED CBI is widely used in systems requiring multi-point indication or progressive signaling: • Multi-Step Status IndicatorsIdeal for equipment that needs to display 4-state operational sequences such as:

• Communication & Monitoring DevicesStacked LEDs are common in:

• Compact Multi-Point Display ModulesThe slim vertical module supports multi-indicator installations without expanding PCB width. • User Interface & Keypad BacklightingProvides structured backlighting for:

• Consumer & Commercial ElectronicsUsed in audio systems, appliances, smart devices, and measurement instruments requiring multi-state indication. • Industrial EquipmentPerfect for rugged environments requiring reliable, high-visibility indicators. Benefits✔ Space-Saving LayoutOne module replaces four individual LEDs, reducing board routing, solder points, and design complexity. ✔ Consistent VisibilityUniform alignment ensures a professional appearance and consistent optical output. ✔ Easy AssemblyPreformed leads accelerate production and reduce manual adjustment errors. ✔ Flexible Color CodingSupports advanced signal mapping using multi-color combinations. ✔ Long-Term ReliabilityRobust materials and LED technology minimize service needs. Case Study: Industrial Control Panel ManufacturerA U.S.-based control panel manufacturer adopted the 3mm quad-level CBI to replace four discrete LEDs used previously in their diagnostic interface. Results:

This upgrade significantly improved both manufacturing efficiency and product user experience. User Testimonials● Mark L., Electronic Systems Engineer ● Sarah T., Product Manager (Instrumentation Industry) ● Daniel R., OEM Developer ConclusionThe 3mm Quad-Level LED CBI (10×4×20mm) is a compact, versatile, and high-performance indicator solution designed for modern electronic systems requiring multi-level visual signals. With its reliable illumination, multiple color options, UL-rated materials, and highly efficient design, it is ideal for applications across industrial, commercial, communication, and consumer markets. If your next project requires dense, multi-state visual indicators with professional performance and long-term stability, this quad-level CBI is the perfect choice. ___________________________________________________________________________________________________________________________________________________ Dimension and Circuit Drawing:  |

Related Article List

Related Information

Soldering

When soldering, leave a minimum of 2mm clearance from the base of the base of the lens to the soldering point. Dipping the lens into the solder must be avoided.

Do not apply any external stress to the lead frame during soldering while the LED is at high temperature.

Recommended soldering conditions:

| IR Reflow Soldering (for SMD display) | Wave Soldering | Soldering Iron | |||

| Pre-Heat | 150-180°C | Pre-Heat | 100°C Max. | Temperature | 300°C Max. |

| Pre-Heat Time | 120sec Max. | Pre-Heat Time | 60sec Max. | ||

| Peak Temperature | 260°C Max. | SolderWave | 260°C Max. | Soldering Time | 3sec Max.(one time only) |

| Soldering Time | 10 sec Max. | Soldering Time | 5sec Max. | ||

Note: Excessive soldering temperature and/or time might result in deformation of the LED lens or failure of the LED

ESD(Electrostatic Discharge)

Static Electricity or power surge will damage the LED.

Suggestions to prevent ESD (Electrostatic Discharge):

n Use a conductive wrist band or anti-electrostatic glove when handling these LEDs

n All devices, equipment, and machinery must be properly grounded

n Work tables, storage racks, etc. should be properly grounded

n Use ion blower to neutralize the static charge which might have built up on surface of the LED’s

plastic lens as a result of friction between LEDs during storage and handling

ESD-damaged LEDs will exhibit abnormal characteristics such as high reverse leakage current,

low forward voltage, or “no light on” at low currents. To verify for ESD damage, check for “light on”

and Vf of the suspect LEDs at low currents.

The Vf of “good” LEDs should be>2.0V@0.1mA for InGaN product and >1.4V@0.1mA for AlInGaP

product.

When selecting power for LED systems, it’s essential to understand several key parameters to ensure safe operation, longevity, and optimal performance. Here are some steps and considerations for LED power selection:

- Determine the Forward Voltage (Vf) of the LED(s):

Each LED has a forward voltage, which is the voltage at which the LED operates when the current is flowing through it. This value can typically be found in the LED’s datasheet.

- Determine the Forward Current (If) of the LED(s):

The forward current is the current at which the LED is designed to operate. Running an LED at higher than its rated current can reduce its lifespan and increase the heat it produces.

- Decide on the Configuration:

Series Configuration: When LEDs are connected in series, the forward voltages add up, but the current remains the same.

Parallel Configuration: When LEDs are connected in parallel, the forward voltage remains the same, but the currents add up. This configuration can be risky because if one LED fails or has a slightly lower forward voltage, it can cause the other LEDs to draw more current.

Calculate Total Power Requirements:

Power (W) = Total Forward Voltage (V) x Total Forward Current (A)

For example, if you have three LEDs connected in series, each with a forward voltage of 3V and a forward current of 20mA, the total power requirement would be:

Power = (3V + 3V + 3V) x 20mA = 9V x 0.02A = 0.18W

- Select an Appropriate Power Supply:

- Voltage Rating: The power supply voltage should match or slightly exceed the total forward voltage of your LED configuration.

- Current Rating: The power supply’s current rating should meet or exceed the total forward current of your LED configuration.

- Safety Margin: It’s a good practice to select a power supply that can provide at least 20% more power than your calculated requirement. This ensures the power supply isn’t operating at its maximum capacity, which can extend its life and ensure safer operation.

- Consider Additional Features:

- Dimming Capability: If you want to control the brightness of your LEDs, choose a power supply with dimming capabilities.

- Overcurrent and Overvoltage Protection: To protect your LEDs, select a power supply with built-in protection mechanisms.

- Thermal Management: Ensure that the power supply has adequate cooling, especially if it will be enclosed or in a location with limited airflow.

- Regulation and Efficiency:A power supply with good regulation will maintain a consistent voltage output despite variations in the load. High efficiency ensures minimal power is wasted as heat.

- Physical Size and Form Factor:Depending on where you plan to place the power supply, its size and shape may be critical factors.

In summary, when selecting power for LED systems, understanding your LED’s requirements and the configuration you plan to use is essential. Then, pick a power supply that meets those needs with some added safety margin, keeping in mind any additional features or constraints relevant to your project.

Here are some well-regarded brands in the industry:

- Mean Well: One of the most recognized brands in the LED power supply industry, Mean Well offers a wide range of products suitable for both indoor and outdoor applications. Their units often come with features like overcurrent protection, dimming capabilities, and high efficiency.

- Tridonic: A global leader in lighting technology, Tridonic offers LED drivers and power supplies that cater to various lighting solutions, from simple setups to advanced smart lighting systems.

- Philips Advance Xitanium: Philips is a well-known brand in the lighting industry, and their Xitanium series of LED drivers are known for reliability and performance. They cater to both indoor and outdoor LED applications.

- Osram: Another giant in the lighting industry, Osram offers a range of LED drivers and power supplies suitable for various applications, including architectural and street lighting.

- LIFUD: Specializing in LED drivers, LIFUD is known for its high-quality products that cater to both commercial and residential LED lighting solutions.

- MOSO: This brand offers a variety of LED drivers, especially for outdoor and industrial applications. Their products are known for durability and performance.

- TDK-Lambda: With a history in power electronics, TDK-Lambda offers a range of power supplies and LED drivers suitable for various applications, emphasizing reliability and advanced features.