Dot Color

Series No:

Weight:(g/pcs)

Dimension:(mm)

Dot height:(mm)

Dot pitch:(mm)

Dot size:(mm)

Specification:

Inquiry

Description:

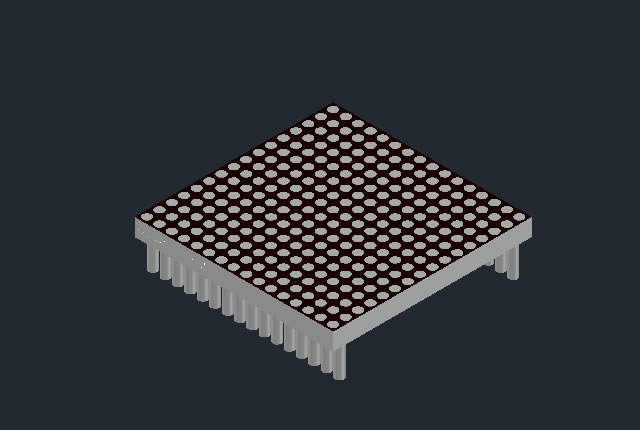

“Innovating Displays: The Precision and Power of the 1.5 Inch Height 16×16 LED Dot Matrix”

Introduction

In the rapidly advancing world of electronic displays, the 16×16 LED matrix has emerged as one of the most versatile and impactful technologies. Whether used for digital signage, text scrolling, or pattern generation, this compact yet powerful component forms the foundation of countless visual communication systems. The LED matrix 16×16, specifically the 1.5-inch height version, offers high resolution, flexibility, and performance — making it a top choice for engineers, manufacturers, and system designers.

As a key component in matrix LED display systems, the 1.5-inch height 16×16 dot matrix can be integrated into both small-scale and large-scale electronic applications. From consumer gadgets to industrial panels, it provides clear, customizable output. Additionally, with LED array display capabilities, these modules are essential for delivering consistent, bright, and energy-efficient visuals.

Features of the 1.5 Inch Height 16×16 LED Dot Matrix

The 16×16 LED matrix display consists of 256 individual LEDs arranged in a grid of 16 rows and 16 columns. Each LED can be controlled individually to display patterns, numbers, or even scrolling text. This modular design allows for flexibility — multiple units can be combined to form larger screens for various applications.

Key Features:

-

Compact 1.5-Inch Height:

The small size makes the display ideal for space-constrained applications, offering high brightness and clarity in a compact footprint. -

High-Resolution Output:

With 256 LEDs, the LED matrix 16×16 provides precise control for detailed graphical or textual representations. -

Uniform Brightness:

Advanced LED technology ensures consistent illumination across the entire display surface, essential for professional-grade visualization. -

Energy Efficiency:

The matrix consumes minimal power compared to older display technologies, making it suitable for battery-powered or energy-sensitive projects. -

Durability and Longevity:

Constructed with high-quality materials, this display offers long operational life with minimal maintenance, even in demanding industrial environments. -

Flexible Control Options:

The matrix LED display can easily be driven using microcontrollers such as Arduino, Raspberry Pi, or dedicated driver ICs for advanced projects.

Applications Across Industries

The adaptability of the 16×16 LED matrix display makes it a preferred solution for a wide range of applications. Its ability to show text, numbers, symbols, and animations ensures its relevance across multiple industries.

-

Consumer Electronics:

Devices such as digital clocks, audio systems, and wearables use LED array displays for compact and informative visual output. The RGB variant allows for multi-color effects, enhancing user experience. -

Industrial Equipment:

In matrix LED display systems for control panels and monitoring equipment, the display provides essential real-time data feedback in harsh conditions. -

Transportation and Public Information:

The LED matrix 16×16 is widely used in digital signboards, number indicators, and scrolling message displays for buses, trains, and stations. -

Educational and Prototyping Platforms:

Electronics enthusiasts and students use these displays in Arduino projects to create text displays, animations, and graphical indicators. -

Commercial Advertising:

Businesses integrate these displays into compact signage systems to showcase dynamic messages and branding, taking advantage of the display’s energy efficiency and visual appeal.

Benefits of Using a 1.5 Inch 16×16 LED Dot Matrix Display

The 16×16 LED matrix offers multiple benefits beyond its compact size and brightness, making it a cornerstone in modern display technology.

-

High Customizability:

Users can program the LED matrix 16×16 to show any desired text or pattern, allowing flexibility in communication and design. -

Wide Viewing Angle:

The display maintains brightness and clarity across a wide range of viewing angles, ideal for public and industrial environments. -

Seamless Scalability:

Multiple 16×16 panels can be connected to create larger matrix LED displays without loss of uniformity or performance. -

Low Maintenance:

With solid-state components and long-lasting LEDs, the display requires minimal maintenance and offers a long service life. -

Cost Efficiency:

Compared to LCD or OLED displays, LED array displays provide an economical solution with excellent visibility and robustness.

Case Studies: Real-World Applications

Case Study 1 – Industrial Control Panel Integration

A manufacturing plant integrated 16×16 LED matrix modules into its machine control panels for status indication. The compact 1.5-inch design allowed operators to monitor data such as temperature and output levels in real-time. The use of matrix LED display technology improved efficiency by 25% due to quicker decision-making.

Case Study 2 – Public Transportation Displays

A city transit authority implemented LED matrix 16×16 panels for bus and train route indicators. The high brightness and reliability of the displays ensured visibility under daylight, reducing passenger confusion and improving scheduling accuracy.

Case Study 3 – Educational Arduino Projects

Students in an engineering program utilized LED array displays to build message boards and visual clocks. The simplicity of programming the 16×16 LED matrix using microcontrollers made it a top educational tool for learning about digital systems and display interfacing.

User Testimonials

Richard Huang, Electronics Engineer (USA):

“The 1.5-inch height 16×16 LED matrix has been an excellent solution for our compact control devices. It provides bright, consistent illumination and works seamlessly with our microcontroller setup.”

Laura Thompson, Product Designer (UK):

“We used the LED matrix 16×16 in our portable devices for status and alert displays. Its low power consumption and flexibility made it an ideal choice for energy-efficient product design.”

Kenta Sato, Automation Specialist (Japan):

“Our industrial systems now use matrix LED displays for operational data. They are durable, easy to integrate, and highly visible in any environment — a huge upgrade over traditional indicators.”

Conclusion

The 1.5 inch height 16×16 LED dot matrix represents a significant advancement in visual display technology. Its compact design, high brightness, and customizable functionality make it suitable for a broad range of applications — from consumer gadgets to matrix LED display systems in industrial automation and public information infrastructure.

Engineers, designers, and manufacturers value its flexibility, longevity, and energy efficiency, while students and developers appreciate its ease of programming and modularity. For any project requiring a reliable, vibrant, and adaptable LED array display, the 16×16 LED matrix is the clear choice for precision and performance in the digital age.

Features

- Matrix Dimensions: The matrix has a height of 40mm and a width of 40.00mm, providing a balanced display area in a compact size.

- Dot Size and Shape: Each dot is 1.80mm in size and circular in shape, offering clarity and precision in display.

- High Dot Count: With 16 columns and 16 rows, the matrix offers a total of 256 dots, allowing for detailed and intricate displays.

- Low Current Operation: Designed for low current usage, it is energy-efficient and suitable for long-term operation without excessive power consumption.

- High Contrast and Brightness: Ensures excellent visibility and readability, even in bright environments.

- Code Compatibility: The matrix is compatible with ASCII and EBCDIC codes, allowing for versatility in programming and display content.

- Horizontal Stackability: It can be stacked horizontally, enabling the creation of larger, more expansive display panels.

- Dual Anode/Cathode Options: Available with both column cathode and anode configurations, providing flexibility for different circuit designs.

- Ease of Mounting: Designed for straightforward mounting on printed circuit boards or sockets, simplifying integration into various projects.

- Luminous Intensity Categorization: The LED dots are categorized for luminous intensity, ensuring uniform brightness across the display.

- Durability: The matrix is technically rugged, offering durability and reliability for various applications.

- Aesthetic Design: Features a standard gray surface with white dots for a professional and neutral look.

- Environmental Compliance: RoHS compliant, indicating environmentally friendly manufacturing processes.

Applications

- Advanced Electronic Signage: Ideal for creating complex and dynamic signs for advertising, public information, or event displays.

- Detailed Information Panels: Suitable for use in transportation systems, control rooms, or public areas for displaying detailed information.

- Interactive Art and Design: Can be used in interactive art installations or design projects due to its high resolution and flexibility.

- Educational Purposes: Useful in educational environments for teaching electronics, programming, or for creating interactive educational tools.

- Gaming and Entertainment Devices: Appropriate for gaming consoles, arcade machines, or other entertainment systems requiring high-resolution displays.

- Customized Clocks and Timers: Perfect for building intricate custom clocks, timers, or countdown devices.

- Industrial Control Panels: Applicable in industrial settings for control interfaces, providing clear and detailed status indicators.

- Prototyping and DIY Projects: An excellent choice for hobbyists and DIY enthusiasts for creating custom lighting solutions, gadgets, or experimental projects.

Electrical-optical characteristics:

Package configuration & Internal circuit diagram

Obtain 3D specification files

To examine all 3D specifications, save the files to your local drive and open them with your 3D application.

Lens colors in 3D files are solely for visual representation; consult the Datasheet for accurate lens type and color information.

In the event of a mismatch, the dimensions in the datasheet take precedence over the 3D specifications.

All dimensions are in millimeters(inches)

Tolerance is +-0.25(0.01″) unless otherwise note

Specifications are subject to change without notice.

Partno description:

More Information

Reflector Surface color (1st number)/ dot Lens color (2nd number):

| Number | 0 | 1 | 2 | 3 | 4 | 5 |

| Ref Surface Color | White | Black | Gray | Red | Green | |

| Dot Epoxy Color | Water clear | White diffused | Red Diffused | Green Diffused | Yellow Diffused |

Absolute maximum ratings (Ta= 25°C)

| Parameter | S | D | UR | E | Y | G | Unit | |

| Forward Current IF | 25 | 25 | 25 | 25 | 25 | 30 | mA | |

| Power Dissipation Pd | 60 | 60 | 60 | 60 | 60 | 65 | mW | |

| Reverse Voltage VR | 5 | 5 | 5 | 5 | 5 | 5 | V | |

| Peak Forward Current IPF (Duty 1/10 @1KHZ) | 150 | 150 | 150 | 150 | 150 | 150 | mA | |

| Operation Temperature TOPR | -40 to +80 | °C | ||||||

| Storage Temperature TSTG | -40 to +85 | °C | ||||||

| Lead Soldering Temperature TSOL | Max.260+ 5°C for 3 sec Max. ( 1.6mm from the base of the epoxy bulb) | °C | ||||||

Absolute maximum ratings (Ta= 25°C)

| Parameter | UHR | UE | YO | UY | UG | PG | UB | UW | Unit |

| Forward Current IF | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | mA |

| Power Dissipation Pd | 75 | 65 | 65 | 65 | 75 | 110 | 120 | 120 | mW |

| Reverse Voltage VR | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | V |

| Peak Forward Current IPF (Duty 1/10 @1KHZ) | 150 | 150 | 150 | 150 | 150 | 150 | 100 | 100 | mA |

| Operation Temperature TOPR | -40 to +80 | °C | |||||||

| Storage Temperature TSTG | -40 to +85 | °C | |||||||

| Lead Soldering Temperature TSOL | Max.260+ 5°C for 3 sec Max. ( 1.6mm from the base of the epoxy bulb) | °C | |||||||

Related Information

Applied for:

1. Application

The Seven Segment LED is widely applied for ordinary electronic equipment (such as office equipment,

communication equipment and household applications). Checking with BETLUX’s Sales in

advance for information on applications in which exceptional reliability is required, particularly

when the failure or malfunction of the LEDs may directly jeopardize life or health (such as in

aviation, transportation, traffic control equipment, medical and life support systems and safety

devices).

2. Storage

The storage ambient for the Seven Segment LED should not exceed 30℃ temperature or 70% relative humidity.

For extended storage out of their original packaging, it is recommended that the Seven Segment LEDs be stored

in a sealed container with appropriate desiccant, or in a desiccator with nitrogen ambient.

3. Cleaning

Avoid using any unspecified chemical solvent to clean LED . For example, Trichloroethylene, Chlorosen, Acetone, and Diflon S3MC.

Any cleaning method can only be taken under normal temperature in one minute or less if it is required.

Use water to clean the Seven Segment LED if necessary under room temperature

dry it immediately after that.

4.Forming

Any unsuitable stress applied to the epoxy may break bonding wires in LED

Any forming on lead pin must be done before soldering, not during or after soldering.

Avoid applying any stress to resin in order to prevent the epoxy fracture and break on bonding wire.

While forming, please use a tie bar cut or equivalent to hold or bend the pin.

2mm from the base of resin is the minimum distance for the place bending the lead pin.

Avoid bending the lead pin at the same point twice or more.

Soldering

When soldering, leave a minimum of 2mm clearance from the base of the base of the lens to the soldering point. Dipping the lens into the solder must be avoided.

Do not apply any external stress to the lead frame during soldering while the LED is at high temperature.

Recommended soldering conditions:

| IR Reflow Soldering (for SMD display) | Wave Soldering | Soldering Iron | |||

| Pre-Heat | 150-180°C | Pre-Heat | 100°C Max. | Temperature | 300°C Max. |

| Pre-Heat Time | 120sec Max. | Pre-Heat Time | 60sec Max. | ||

| Peak Temperature | 260°C Max. | SolderWave | 260°C Max. | Soldering Time | 3sec Max.(one time only) |

| Soldering Time | 10 sec Max. | Soldering Time | 5sec Max. | ||

Note: Excessive soldering temperature and/or time might result in deformation of the LED lens or failure of the LED

ESD(Electrostatic Discharge)

Static Electricity or power surge will damage the LED.

Suggestions to prevent ESD (Electrostatic Discharge):

n Use a conductive wrist band or anti-electrostatic glove when handling these LEDs

n All devices, equipment, and machinery must be properly grounded

n Work tables, storage racks, etc. should be properly grounded

n Use ion blower to neutralize the static charge which might have built up on surface of the LED’s

plastic lens as a result of friction between LEDs during storage and handling

ESD-damaged LEDs will exhibit abnormal characteristics such as high reverse leakage current,

low forward voltage, or “no light on” at low currents. To verify for ESD damage, check for “light on”

and Vf of the suspect LEDs at low currents.

The Vf of “good” LEDs should be>2.0V@0.1mA for InGaN product and >1.4V@0.1mA for AlInGaP

product.

LED dirve IC by Maxim Integrated

MAX6959 4½-Digit LED Display Driver

MAX6958 4½-Digit LED Display Driver

MAX6955 7-, 14-, 16-Segment LED Display Driver

MAX6956 LED Static Display Driver and I/O Port

MAX6954 7-, 14-, 16-Segment LED Display Driver

MAX6952 5 x 7 Matrix LED Display Driver

MAX6957 LED Static Display Driver and I/O Port

MAX6950 5-Digit LED Display Driver

MAX6951 8-Digit LED Display Driver

ICM7212 4-Digit LED Driver

ICM7212A 4-Digit LED Driver

ICM7212AM 4-Digit LED Driver

ICM7212M 4-Digit LED Driver

ICM7218A 8-Digit LED Driver

ICM7218B 8-Digit LED Driver

ICM7218C 8-Digit LED Driver

ICM7218D 8-Digit LED Driver

MAX7221 8-Digit LED Display Driver

MAX7219 8-Digit LED Display Driver

When selecting power for LED systems, it’s essential to understand several key parameters to ensure safe operation, longevity, and optimal performance. Here are some steps and considerations for LED power selection:

- Determine the Forward Voltage (Vf) of the LED(s):

Each LED has a forward voltage, which is the voltage at which the LED operates when the current is flowing through it. This value can typically be found in the LED’s datasheet.

- Determine the Forward Current (If) of the LED(s):

The forward current is the current at which the LED is designed to operate. Running an LED at higher than its rated current can reduce its lifespan and increase the heat it produces.

- Decide on the Configuration:

Series Configuration: When LEDs are connected in series, the forward voltages add up, but the current remains the same.

Parallel Configuration: When LEDs are connected in parallel, the forward voltage remains the same, but the currents add up. This configuration can be risky because if one LED fails or has a slightly lower forward voltage, it can cause the other LEDs to draw more current.

Calculate Total Power Requirements:

Power (W) = Total Forward Voltage (V) x Total Forward Current (A)

For example, if you have three LEDs connected in series, each with a forward voltage of 3V and a forward current of 20mA, the total power requirement would be:

Power = (3V + 3V + 3V) x 20mA = 9V x 0.02A = 0.18W

- Select an Appropriate Power Supply:

- Voltage Rating: The power supply voltage should match or slightly exceed the total forward voltage of your LED configuration.

- Current Rating: The power supply’s current rating should meet or exceed the total forward current of your LED configuration.

- Safety Margin: It’s a good practice to select a power supply that can provide at least 20% more power than your calculated requirement. This ensures the power supply isn’t operating at its maximum capacity, which can extend its life and ensure safer operation.

- Consider Additional Features:

- Dimming Capability: If you want to control the brightness of your LEDs, choose a power supply with dimming capabilities.

- Overcurrent and Overvoltage Protection: To protect your LEDs, select a power supply with built-in protection mechanisms.

- Thermal Management: Ensure that the power supply has adequate cooling, especially if it will be enclosed or in a location with limited airflow.

- Regulation and Efficiency:A power supply with good regulation will maintain a consistent voltage output despite variations in the load. High efficiency ensures minimal power is wasted as heat.

- Physical Size and Form Factor:Depending on where you plan to place the power supply, its size and shape may be critical factors.

In summary, when selecting power for LED systems, understanding your LED’s requirements and the configuration you plan to use is essential. Then, pick a power supply that meets those needs with some added safety margin, keeping in mind any additional features or constraints relevant to your project.

Here are some well-regarded brands in the industry:

- Mean Well: One of the most recognized brands in the LED power supply industry, Mean Well offers a wide range of products suitable for both indoor and outdoor applications. Their units often come with features like overcurrent protection, dimming capabilities, and high efficiency.

- Tridonic: A global leader in lighting technology, Tridonic offers LED drivers and power supplies that cater to various lighting solutions, from simple setups to advanced smart lighting systems.

- Philips Advance Xitanium: Philips is a well-known brand in the lighting industry, and their Xitanium series of LED drivers are known for reliability and performance. They cater to both indoor and outdoor LED applications.

- Osram: Another giant in the lighting industry, Osram offers a range of LED drivers and power supplies suitable for various applications, including architectural and street lighting.

- LIFUD: Specializing in LED drivers, LIFUD is known for its high-quality products that cater to both commercial and residential LED lighting solutions.

- MOSO: This brand offers a variety of LED drivers, especially for outdoor and industrial applications. Their products are known for durability and performance.

- TDK-Lambda: With a history in power electronics, TDK-Lambda offers a range of power supplies and LED drivers suitable for various applications, emphasizing reliability and advanced features.

Need help?

No related products found.